Litho Laminated Printed Packaging

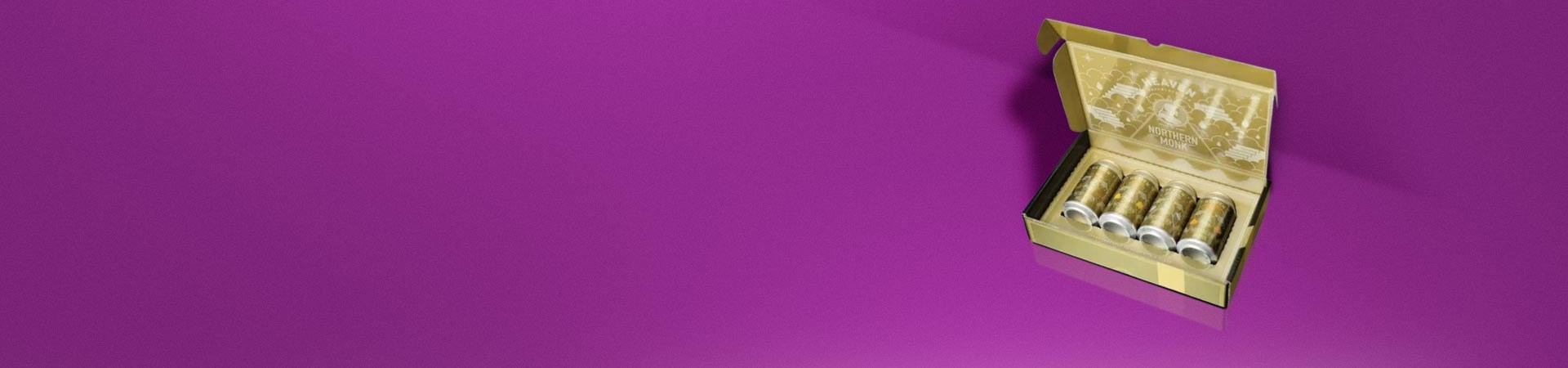

Manufacturer and supplier of premium photo quality custom printed cardboard boxes with logo in the UK.

With a high percentage of purchasing decisions being influenced by visual perception alone, the use of high quality and luxury printed packaging boxes continues to grow.

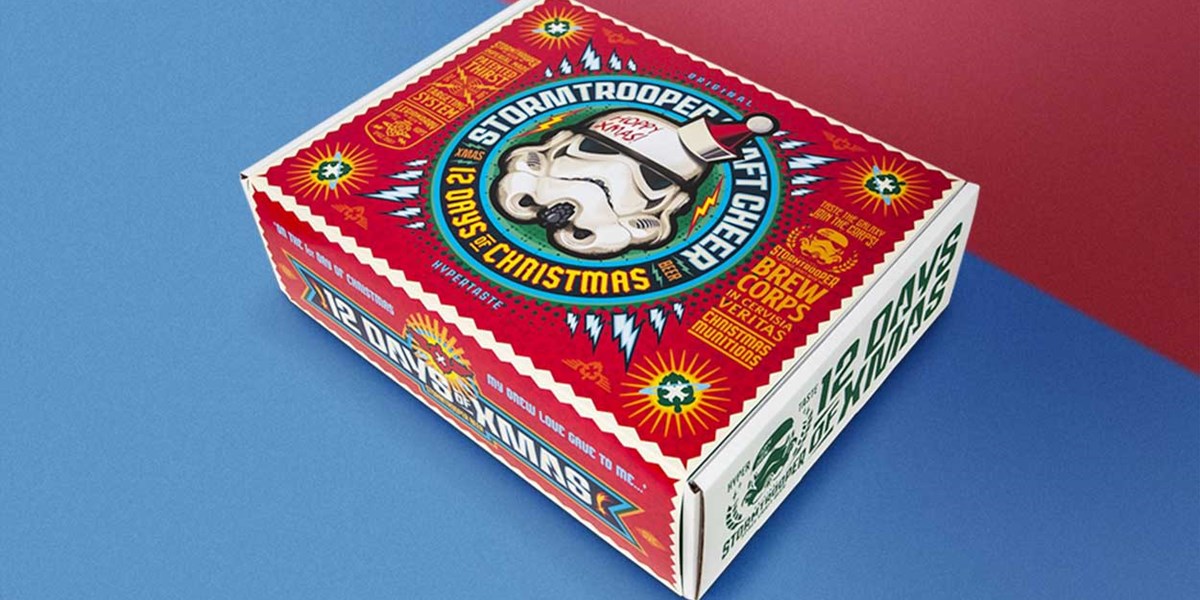

Brand owners are very much aware of the power and quality of litho laminated print packaging, and how this printing process can result in eye-catching photographic quality print, ideal to attract consumer attention and showcase both their product and brand with a high-quality visual experience.

More about litho printed packaging

We supply high-end and luxury bespoke litho printed packaging solutions to many industries and understand that quality and consideration for your brand are key.

Working to your product’s specifications, we can help your business benefit from memorable packaging solutions that will stand out against the crowd, encourage consumer purchasing and deliver lasting positive brand experiences.

The litho print process is great for brands who require high-quality, luxury print for product packaging. If you need your packaging deliver a show-stopping experience for your customers, litho printed packaging may be perfect for your business.

Download our ‘Why Go Litho?’ infographic.

At Saxon Packaging we outsource litho printing to our (approved) trade partners which gives us the flexibility to select the most appropriate press size for your chosen box. Selecting the best press size allows us to offer the most overall cost effective solution for your litho printed packaging requirement.

Using our in house film laminator we can offer different print finishes that provide added durability and premium finishes such as gloss, matt and soft-touch. Further embellishments can be made by adding specialist varnishes and block-foiling to provide the most premium of appearances. For more detail on print finishes click here.

This litho printed, film laminated sheet is then mounted in house using our litho laminator to the base substrate (such as E, B, EB corrugated board or solid board materials) before it is transferred to the die-cutting and gluing stations.

By having control and extensive knowledge of the process involved, we are able to provide you luxury and best quality litho printed packaging at the most competitive rates in the UK.Along with standard print options, additional print finishes and embellishments are available to add further enhancements to both your product packaging and branding.

Decorative embellishments:

- Foil blocking

- Textured, rough & soft-touch laminate or varnish

- Spot UV

- Embossing & debossing

- Matt & high gloss

- Glitter, pearlescent finishes

- Glow-in-the-dark printing

- Fragrance bursts

Do I need to order a minimum quantity?

We don’t have a minimum order quantity. We have the ability to produce ‘one-offs’ and low volumes if required, but we do have cost-effective minimum order quantities which are determined by the area of material used, material type, style of box and print requirement.

Can you explain price per 1000?

If you have a price for 1000 boxes @ £550 / 1000, imagine it as a unit cost of 55p each. Likewise a quote for £700 /1000 equates at 70p each.

What are cutting forme and stereo costs?

Cutting formes are used to cut the packaging into the correct shape. Stereos are used for flexo printed packaging. This enables the packaging to be printed bespoke to the client’s requirement. Both the ‘cutting forme’ and the ‘stereo’ belong to the customer.

Do you hold stock of corrugated boxes, cases and cartons?

We do not hold stock but we do hold materials and cutting tools to provide a fast turnaround on some of the most frequently used packaging lines.

Can you work with us to design a pack from scratch and bespoke to my needs?

Yes, we pride ourselves on working closely with our customers from consulting to design and through to the finished product. We have an in-house design team who are able to design packaging solutions specific to your requirements.

How do I know which print option is right for my requirement?

It all depends on the artwork complexity, number of colours required and quantity of packaging. Our infographic guide to print processes will help steer your required option, but a member of our sales team will always discuss the various options with you to ensure the print option is the most economical and of the required quality.“We have worked with Saxon since day one as we know they value quality & design as highly as we do.” Ivana Walthorne, Seedlip Drinks

“We have worked with Saxon Packaging for a number of years; their support throughout this project was seamless as ever. Saxon provided an innovative solution to a tricky and compact design, delivering within a tight deadline. We are thrilled with both the design and quality of the final pillow packs and have received great feedback from consumers. Thank you Saxon for your continued support!” Mary McAneney, Diageo (Æcorn Drinks)

You may also be interested in